Some Tips to Consider Test Equipment Calibration Services

Test equipment calibration is critical to maintaining accuracy, reliability, and compliance in various industries, including manufacturing, healthcare, aerospace, and telecommunications. This article will explore five compelling reasons businesses should invest in test equipment calibration services.

Ensuring Accuracy and Reliability

Calibration ensures that test equipment provides accurate and reliable measurements essential for maintaining product quality, safety, and regulatory compliance. Over time, equipment can drift or become less accurate due to usage, environmental conditions, or component wear. Regular calibration by certified professionals ensures that equipment remains within acceptable tolerances and delivers precise measurements consistently.

Meeting Regulatory Requirements

Many industries are subject to regulatory requirements and standards that mandate test equipment calibration. Failure to comply with these regulations can result in fines, product recalls, or legal consequences. Test equipment calibration services help businesses meet regulatory requirements and demonstrate compliance with industry standards, ensuring the integrity of their products, processes, and operations.

Improving Product Quality and Performance

Accurate test equipment is essential for maintaining product quality and performance standards. By calibrating measurement devices to traceable standards, businesses can identify and rectify deviations or variations in product quality early in the production process. This helps to minimise defects, rework, and waste, ultimately improving product quality, consistency, and customer satisfaction.

Optimising Equipment Lifespan

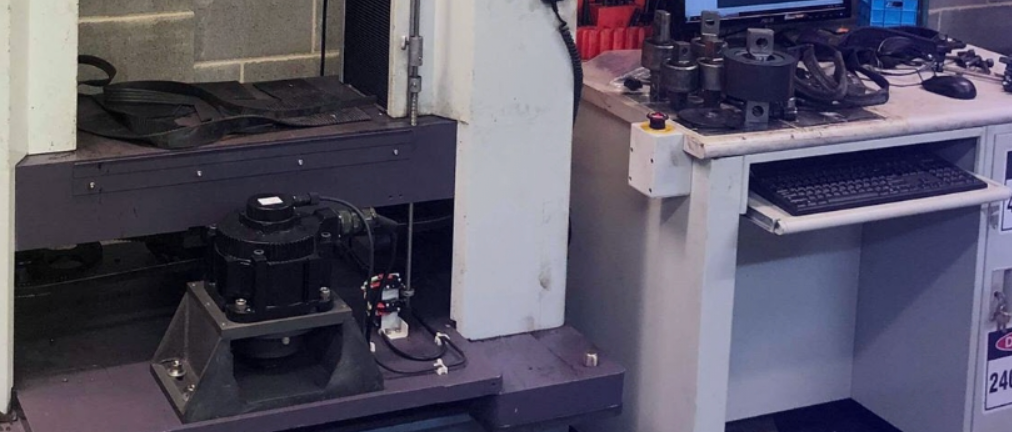

Regular calibration by utilising a dynamic testing machine helps prolong test equipment’s lifespan by identifying and addressing issues before they escalate. Calibration can detect early signs of wear, drift, or malfunction, allowing for timely adjustments, repairs, or replacements. By maintaining equipment in optimal condition, businesses can maximise uptime, minimise downtime, and extend the lifespan of their valuable assets, thereby reducing overall operational costs.

Enhancing Traceability and Documentation

Calibration services provide businesses with comprehensive documentation and traceability records for their test equipment. This documentation includes calibration certificates, calibration reports, and equipment logs that detail the calibration history, results, and any adjustments made during the process. Having accurate and up-to-date calibration records is essential for audits, quality assurance, and regulatory compliance purposes, providing businesses with confidence in the accuracy and reliability of their measurement systems.

Supporting Preventive Maintenance Programs

In addition to ensuring accuracy and reliability, test equipment calibration services also support preventive maintenance programs. Regular calibration checks can help identify potential issues or deviations in equipment performance before they escalate into costly problems or failures. By incorporating calibration into a comprehensive preventive maintenance strategy, businesses can proactively address equipment issues, minimise downtime, and extend the lifespan of their test equipment. This proactive approach reduces the risk of unexpected breakdowns and helps optimise equipment performance, enhance productivity, and support overall operational efficiency. Therefore, investing in test equipment calibration services is a proactive measure contributing to long-term equipment reliability and operational success.

Conclusion

Test equipment calibration services ensure accuracy, reliability, and compliance in various industries. By investing in calibration services, businesses can maintain accurate measurements, meet regulatory requirements, improve product quality and performance, optimise equipment lifespan, and enhance traceability and documentation. With the assistance of certified calibration professionals, businesses can ensure the integrity of their measurement systems and maintain a competitive edge in today’s demanding marketplace.

Leave a Reply